If you follow me on Instagram you already saw, that I finished my Delphos quite some time ago, but I just hadn’t found the time to write a blog post.

I also redid my website and I’m currently preparing my new website which will be linked to my future web-shop, since I plan to start selling historical underwear, accessoires and making historical reproductions. I also plan to take commissions, but since I still work a normal day job I won’t be able to start everything at one.

But today I finally can show you how my Fortuny gown came to life!

I first started with trying out some pleating techniques I found online.

I tried running stitches for making the pleats which did not work at all – you also could see where my needle punctured the fabric which was super ugly, I tried twisting the fabric super tight which also was not very pretty (but I think this is how Fortuny does their silk scarves nowadays…which are not pretty if you ask me).

And then I had to put on my thinking hat. I remembered that I had a teacher in school who was very into japanese dying and pleating methods. I knew that Mariano Fortuny and his wife got their fabrics from japan so I tried to find a connection and I found one! There is a dying/pleating technique named ‚Arashi Shibori‘. And this is exactly how I made my Fortuny dress.

But before pleating my fabric I had to get my fabric and dye it. I bought a super light silk habotai and dyed it with a fabric dye from Kreul. The gold fabric paint is also from them. I also tried out another fabric dye but it came out spotty and very dull.

My glass beads were custom made for me with Murano glass rods and real gold leaf and I love them!

So let’s start pleating!

What did I need for 4 lengths of fabric?

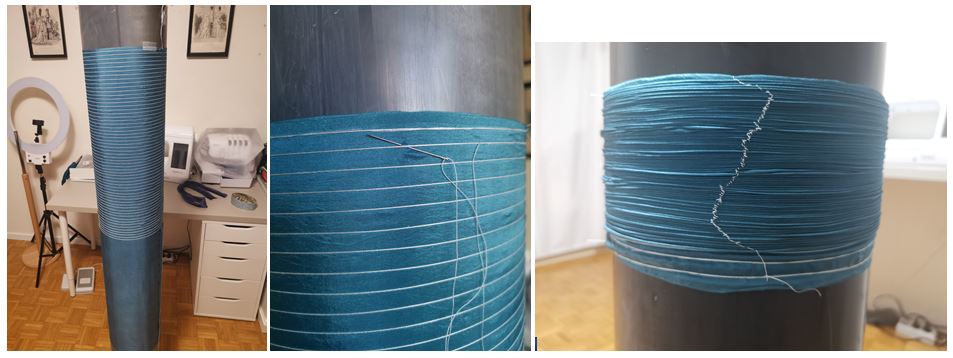

1 PVC pipe with a diameter of 22.5 cm, which is at least as long as the fabric.

2 rolls of thin crochet thread (doesn’t matter how thin, but it needs to be strong)

some Tixo

sewing needle + thread

Spray starch (500ml water, 1 tbsp rice flour boiled up and a good shot of cheap vodka added at the end so it doesn’t start to ferment immediately)

Hot water with a good dash of vinegar

Step 1:

The very first thing I did was to wind my fabric panels onto the roll with the right side of the fabric and the finished hem facing outwards and fix them with some Tixo. It is important that the hem runs vertically along the roll. Then I sewed on my crochet yarn with two stitches at the end point of the hem. Perpendicular to the hem I also pinned the fabric with very fine pins. It doesn’t have to be super tight, but it shouldn’t be too loose either.

Step 2:

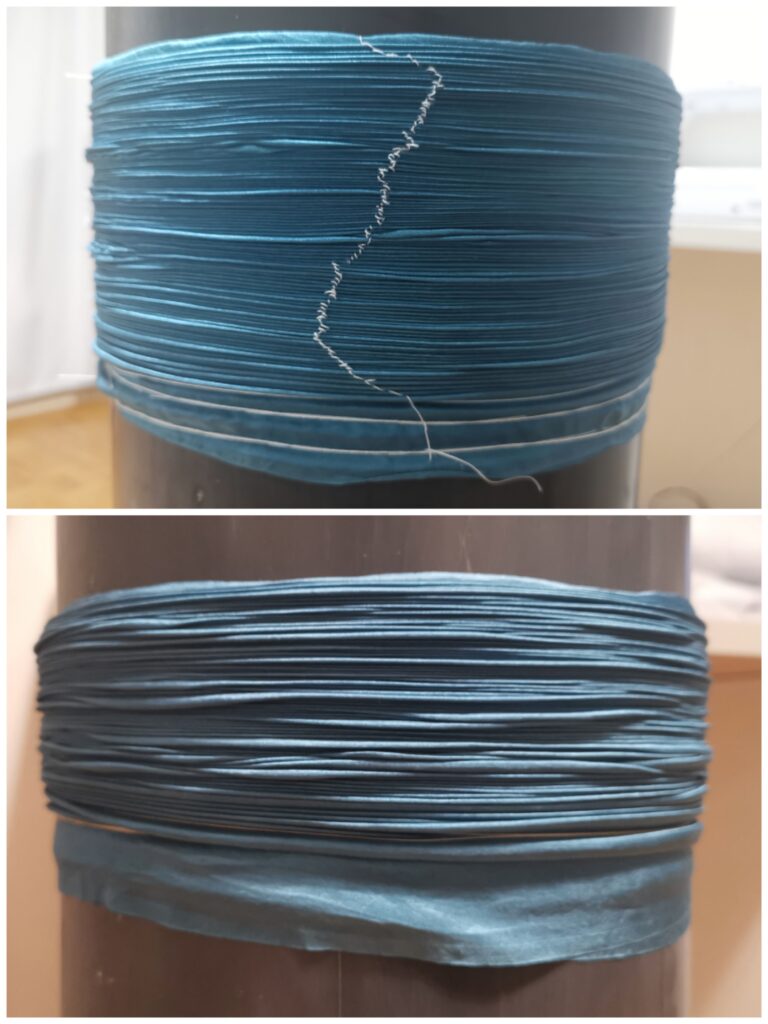

Time to get a ‚Drehwurm‘: You start to wind the crochet yarn around the fabric at a maximum distance of 10 mm. I roughly orientated myself at 8 mm, so if it got a little more or less, it was not a big deal.

not too bad.

Once you have wrapped the yarn completely around the fabric, you sew it down again with two stitches at the bottom.

Step 3:

Using normal sewing thread, sew the first and last 2-3 rows in place with large stitches all the way around and then sew down four times vertically so that the rows can’t slip so much. I tried it without sewing it down and it was so uneven that I had to open it all up again.

Step 4:

Start pushing the fabric together slowly and as evenly as possible. I always started from the top and a little later pushed the fabric up from the bottom as well. If rows were obviously very out of place, I carefully pulled the folds into shape with my fingers and a pin. At the end I tied a twill tape above and below the pleats to prevent the ends of the fabric from slipping away.

Very important: Now remove the vertical securing seams!

Step 5:

Put the tube in the bathtub and „wash“ the tube and the fabric once with hot water.

Then I poured the hot water with the vinegar over the fabric and let it drip off briefly. And then I just sprayed on my spray starch. I can’t tell you how much it was, I just sprayed until it felt right.

And then it was a case of waiting. The tube stood in the warm bathroom right next to the heater and was allowed to dry there for at least 24 hours at a time. I also activated the hairdryer in between, but that’s not a must.

Step 6:

Once the fabric was dry, I used the edge of the hot iron to press these grooves into the fabric. After that, I simply removed the remaining securing seams and the crochet thread (Hello Drehwurm, my old friend) and then I pulled the fabric off with gentle force. This was a very exciting experience, because it was somehow firm and soft at the same time and made a very dusty sound.

And voila: A Fortuny panel is finished.

And have fun: You can do the whole thing 3 more times!

And here are all my Fortuny panels. I just LOVE how they looked.

The belt was a real quick and dirty project.

I looked for a real Fortuny pattern that I liked and made a template. I simply took a firm plastic foil and worked on it with a scalpel. And kids: these things are sharp!

Then I just took the template, put it on a leftover piece of my silk and applied the colour with fabric paint from Kreul and a sponge.

The belt was sewn quickly: two layers of strong cotton, glued with adhesive fleece and covered with the fabric. Then two beads and loops and two hidden hooks and eyes were sewn on and it was finished.

And then all what was left was sewing together the panels. Sadly I didn’t take pictures of this but I just sewed the selvedges together by machine. The pleats on the shoulders were secured by threading them on some strong sewing thread.

and then I sewed on the silk string while threading on the glass beads. They stay where they are because the string is completley sewn onto the fabric. At the end I connected the shoulders with the beads. And then suddenly I was done.

Real photos and what I would change will be in the next post 🙂